We offer comprehensive support services covering epitaxial products to meet all customer needs.

We will do all we can do to assist customers by providing epitaxial production ranging from equipment and parts to technological services.

General

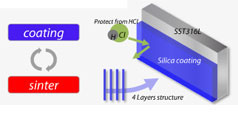

・SiO2 totalthickness : 0.5um

・Heat resistance : 900 degC

Catalog

・Carry with convenient carrying case

・Easy to hook up (Required only CDA)

・Connect to Laptop/PC via USB

・Record into hard disk drive

High quality mode:2,520hr

Standard mode:5,260hr

・1/7″ LCD

・1TB HDD

・Mounting bracket

・CCDcamera

・Cooling sheath

・Carry case

・Manual

・For 200mm and 300mm

・Easy operation by touch panel

・Lift Up/Down check

・Rotation homing check

・Display moving speed

・Auto-sequence check

・Pressurized leak check

・Wobbling check with laser sensor

・Control Box

・Rotation stand

・Leak check kit

・Wobbling check kit

C-Cube The fully modernized Epi controller.

Catarog

・AMC7810/20、P-7700ML/AL

・Compatible with the original controller.

・Heip-function for each screen item.

・Signal and process logging

・User additional Signal I/O

・SPC for process and tool management

Constituted with the Japanese-made part helps the prolongation of life of equipment with various functions date management or the interface which is easy to use.

・Touch pen(standard accessory)can be used as light pen.

・Environment conscious, save 72% rated power.

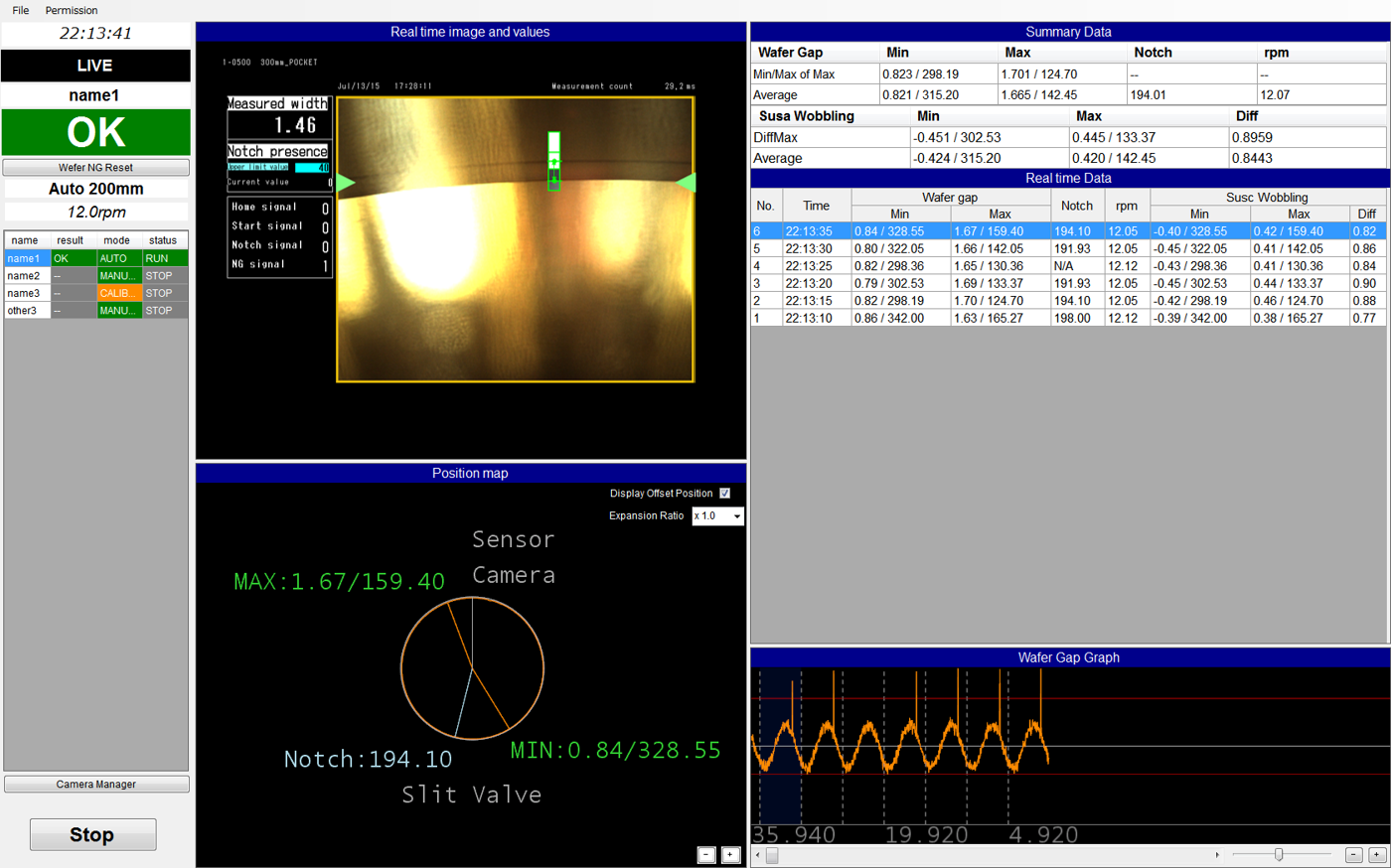

Edge Zoom can measure the gap between wafer edge and susc pocket edge.

・Can capture around wafer edge by special ccd during process temp at 1100C.

・Measure the gap in pocket and analyze a wafer position in pocket

・Rotation actual speed can be measured

・Measured result is stored in SQL DB and can be accessed

TCS Feed System

"TCS FEED SYSTEM" is configured mainly consisting of a vaporizer for gasifying TCS liquid and a condenser for liquefying TCS gas, Facilities of acceptance and the with drawal of the TCS by a tank lorry, and wet process exclusion equipment can be possible packaged. Multiple EP of the furnace at any time of the operation at all Multiple EP of the furnace either at the time of the operation at all, "TCS GAS INSUFFLATION SYSTEM" is High precision concentration adjusted for the TCS/H2 in the mixed gas.

What kind of equipment are you looking for? First of all, please contact us.

Please feel free to ask.+81-957-49-6100Reception Time 9:00 A.M. to 17:00 P.M.(Flexible) [Sun, Sat, and holidays are closed. ]